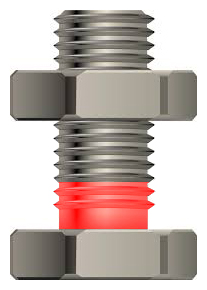

Lock

Description

Insufficient tightening torque, Unsuitable geometric ratios, Differences in the nuances of materials, Frequent variations in temperature or load, Assemblies subjected to vibrations or shocks are all factors that lead to the relaxation of the metal, to the loss of tension, and to the loosening of threaded assemblies.

LOCK B 15 BLUE – low resistance for easy dismantling with all common hand tools, release torque 15 N / m

LOCK R 25 RED – medium resistance for dismantling with all standard professional tools, loosening torque 25 N / m

LOCK V 29 GREEN – high resistance for dismantling with suitable tools or after sublimation at temperature + 250 ° C, loosening cut 29 N / m

LOCK V 29 is also used as a press block fixing for the assembly of fittings with clearance or tight fits. Fixings of bushings, bearings, seals, toothed wheels on transmission shafts, rotors on electric motor shafts, etc.

LOCK thread lockers ensure a constant clamping force, even during mechanized tightening at the angle, at the elastic limit of the screw, fill the voids regardless of the surface roughness of the contacts, consequently ensure the tightness of the assemblies, prevent oxidation generated by external agents, and corrosion of surface tribo-contacts (Hertzian contacts) generated by vibratory phenomena causing pitting.

A thread lock is selected

- Depending on the desired ease or resistance to loosening

- Depending on temperature

- Depending on the grade of the steels in contact

- Depending on the external agents in contact with the assembly, oil, glycols, solvents, etc.

Many recognized producers or Commercial Companies have always, for marketing reasons, extended a single formula to multiple commercial references to “specialize” their range.

Faced with the multitude of specific products and color codes, the LOCK range simplifies the choice, purchases and management of your stocks.

The 3 LOCK products meet all cases.

Applications

Braking on threaded elements:

- threaded assemblies

- screwed connections

- rigid, removable or not removable

- bolts (screws + nuts)

- blind or through tapped holes

- studs

- axles including through them

Threadlocker polymerizes in the absence of air and in the presence of metal particles. Once cured, the threadlocker ensures that the binding is resistant to loosening forces, vibrations and shocks.

Packaging

LOCK B 15 Low braking

LOCK R 25 Medium braking